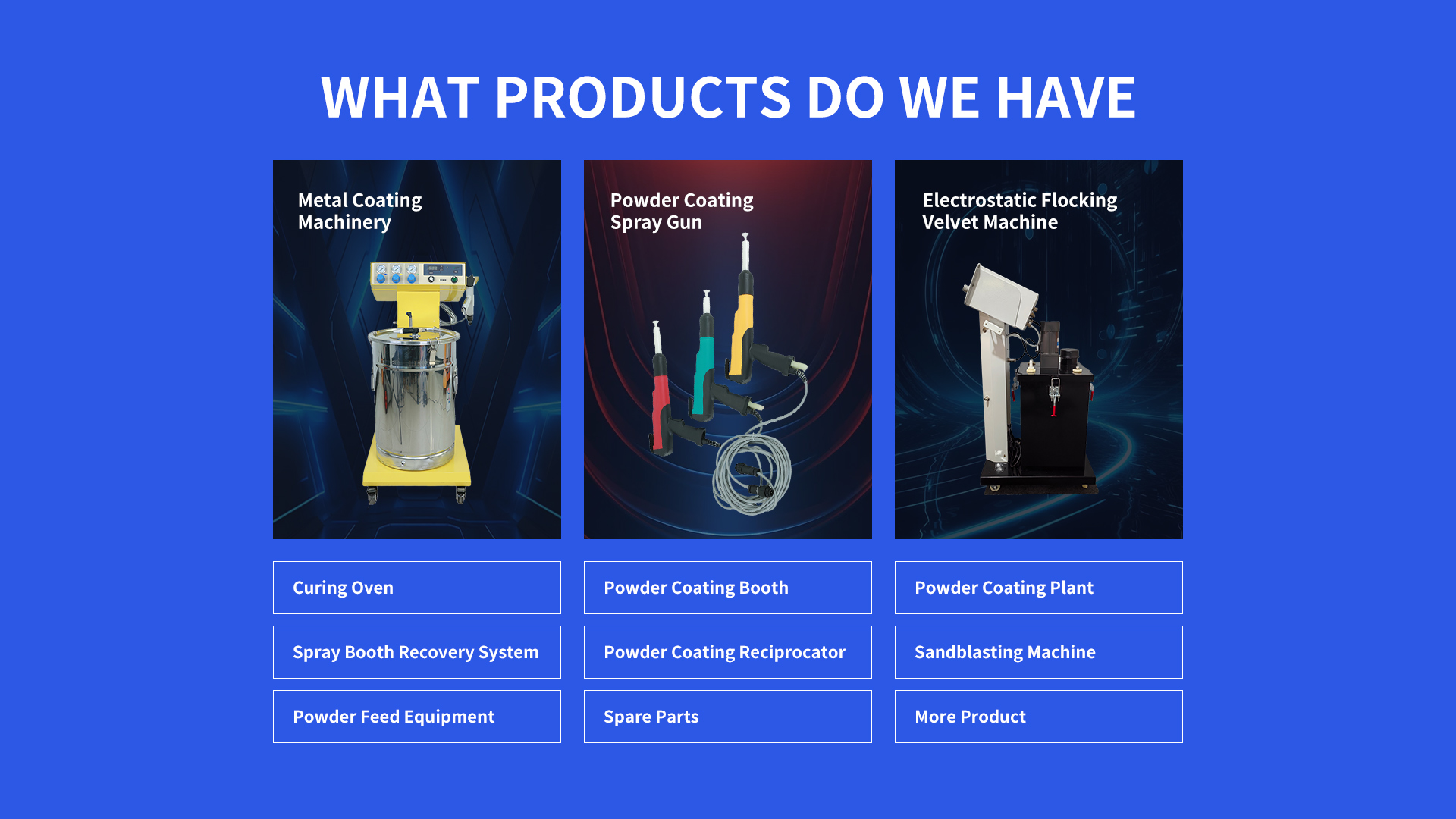

1. Powder Coating Equipment Package Supplier Overview and Components

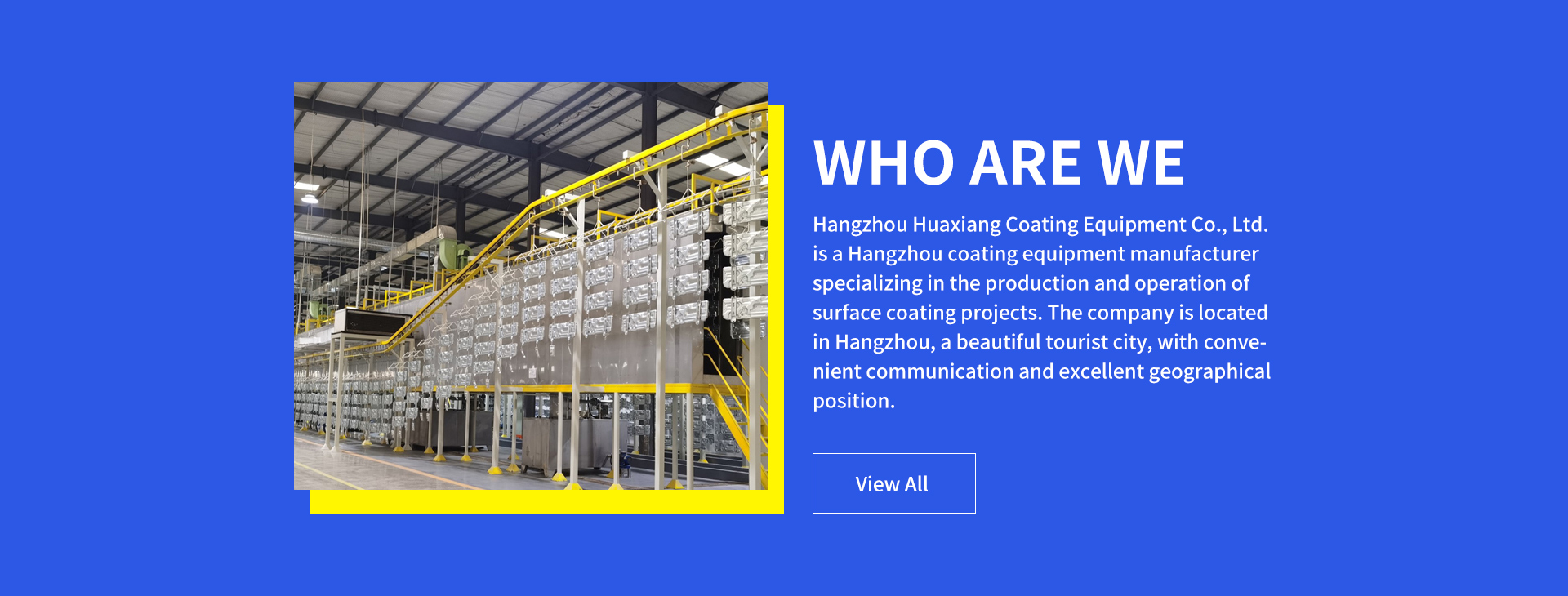

A Powder Coating Equipment Package Supplier provides integrated systems for industrial coating operations. Key offerings include electrostatic spray guns, pre-treatment units, curing ovens, powder recovery systems, and conveyor lines. Leading suppliers like GEMA and Wagner deliver customizable solutions with robotic automation, IoT controls, and modular designs. These packages ensure efficient, uniform coating application for metals, plastics, and ceramics, tailored to client-specific production needs.

2. Applications of Powder Coating Equipment Package Supplier

Suppliers cater to automotive, aerospace, appliance, and construction industries. Their systems coat car parts, aircraft components, household appliances, and architectural steel. Suitable for materials like aluminum, steel, and heat-resistant plastics, these packages deliver durable, corrosion-resistant finishes for high-performance applications.

3. Pricing of Powder Coating Equipment Package Supplier

Costs range from 50,000forbasicmanualsetupsto1 million+ for fully automated lines. Entry-level packages suit small workshops, while high-speed robotic systems serve large factories. Factors like automation level, brand reputation, and after-sales support (e.g., warranties, training) influence pricing.

4. Proper Usage of Powder Coating Equipment Package Supplier

Pre-treatment: Degrease and pre-coat surfaces for optimal adhesion.

Automated Spraying: Program robots for precise voltage (30–100 kV) and spray patterns.

Curing: Bake parts at 350–450°F for 10–30 minutes.

Recovery: Recycle 90%+ excess powder via cyclone systems.

Maintenance: Clean equipment daily and inspect heating elements weekly.

5. How to Choose a Powder Coating Equipment Package Supplier

Production Needs: Match throughput (e.g., 500–5,000 parts/day) to demand.

Technical Support: Prioritize suppliers offering 24/7 assistance and training.

Energy Efficiency: Opt for insulated ovens and energy recovery units.

Compliance: Ensure systems meet OSHA, EPA, and ISO standards.

6. Safety Precautions for Powder Coating Equipment Package Supplier

Use explosion-proof ventilation in powder-handling zones.

Train staff on electrostatic safety and emergency protocols.

Wear PPE (respirators, anti-static suits) to minimize health risks.

Regularly inspect grounding systems and electrical wiring.

7. Design Rationale of Powder Coating Equipment Package Supplier

Suppliers prioritize scalability, sustainability, and smart manufacturing. Robotic arms enhance precision, IoT sensors optimize resource use, and stainless steel construction ensures longevity. Closed-loop powder recycling minimizes waste, aligning with eco-friendly practices.

8. Q&A on Powder Coating Equipment Package Supplier

Q1: What is the ROI of automated supplier systems?

A: High-volume users achieve ROI in 2–3 years via reduced labor and material waste.

Q2: Can suppliers customize packages for niche industries?

A: Yes, tailored solutions are available for sectors like medical devices or electronics.

Q3: How critical is after-sales support from suppliers?

A: Vital for troubleshooting, parts replacement, and minimizing downtime.

Q4: Do suppliers offer eco-friendly options?

A: Yes, zero-VOC processes and energy-efficient designs are standard.

Q5: What training do suppliers provide?

A: Most offer onsite training for equipment operation, safety, and maintenance.

This guide equips businesses with key insights into selecting a Powder Coating Equipment Package Supplier, ensuring efficient, safe, and scalable coating solutions for industrial growth.

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com